November 2018

FLIR A6750sc research grade thermal camera

Additive Manufacturing (AM), also known as 3D Printing Additive Manufacturing (AM), also known as 3D Printing

FLIR Systems reports how its research grade thermal imaging cameras are helping researchers better understand the role of temperature in the construction of 3D-printed components.

Additive Manufacturing (AM), also known as 3D Printing, is revolutionizing manufacturing, because it uses computerized or digital models to generate simple parts and complex components, and adds material only where it is needed.

A growing number of high-tech organizations around the world are using AM technologies to use in applications ranging from product development to specialized manufacturing, in ways as diverse as architectural design, aerospace components, and medical implants.

Disadvantages 3D prining and improving print quality with thermal cameras

Unfortunately, 3D printed parts sometimes suffer from low quality, which is most often due to an unknown cause-and-effect relationship between a manufacturing process parameter, such as a polymer needing to be heated to a specific temperature, and process characteristics, such as part geometry and significant distortion as a result of cooling rate. Too often, process parameters are set using trial-and-error techniques, which are time-consuming, costly, highly subjective, and machine- and/or material-specific.

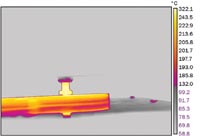

Thermal image of a carbon-based polymer AM process.

This higher contrast image helps show a band material

that is hotter than the layers above and below it.

This uneven temperature distribution can lead to warping.

Thermal cameras are proving their value in advancing a wide range of emerging AM technologies by offering researchers and material scientists the accurate results needed to fine-tune materials, equipment, and process parameters while reducing development time and expenses.

By studying the 3D printing process and its thermal properties with thermal cameras, manufacturers have been able to make quick corrections with minimal production delays.

Why just thermal cameras

Research grade thermal cameras, because of their high thermal sensitivities (down to 0.018 °C) and small spatial resolution capabilities (as small as 3.5 µm per pixel), are able to monitor the effect of changes to

3D printer settings and base materials. And, because they offer non-contact temperature measurements of up to 1 million points in a single thermal image, these thermal cameras are capable of identifying sources of quality problems, including part porosity, delamination, shrinkage, poor surface finish, dimensional or form errors, and thermal stresses and distortion. With Additive Manufacturing expected to continue its rapid growth and adoption in the coming years, the use of thermal cameras will be a key tool in ensuring that processes are optimized to provide uniform, quality parts. |